Cupboard

Compact Modular Kitchens

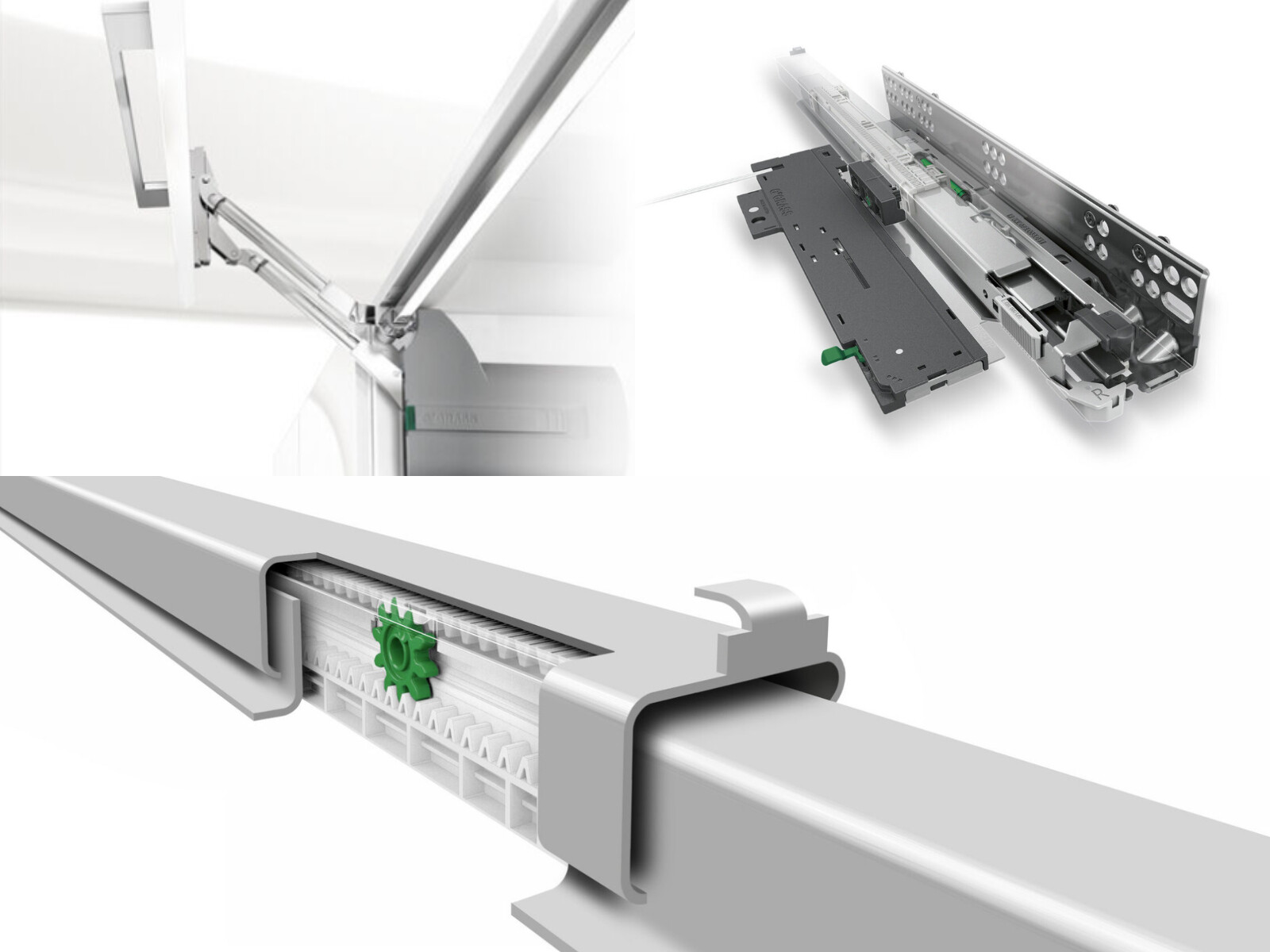

Our modular system reimagines the kitchen as a piece of sophisticated furniture. Designed for simplicity and style, it offers a fully equipped culinary solution that is incredibly easy to install.

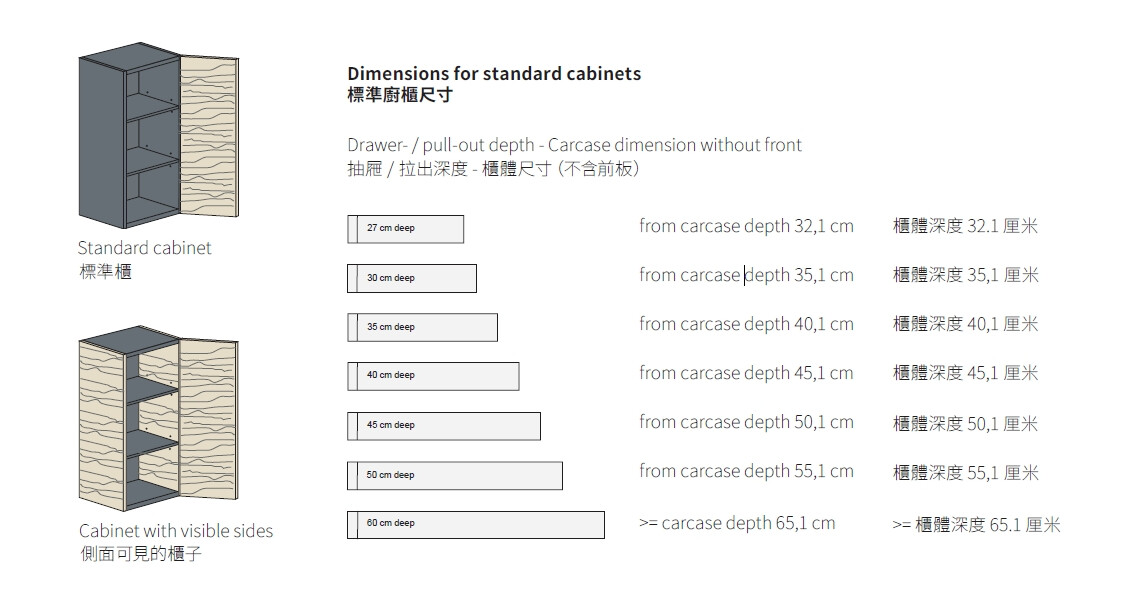

Perfectly suited for compact living spaces, this system maximizes functionality within a minimal footprint, effectively saving both time and cost. It integrates all the essentials—premium cabinetry, a spacious countertop, a large-format sink, and built-in appliances—into one cohesive unit. It is a complete, self-contained kitchen ecosystem designed for efficient storage, cooking, and cleaning.